Desiccant dehumidifier

Working principle of the industrial desiccant (adsorption) dehumidifier

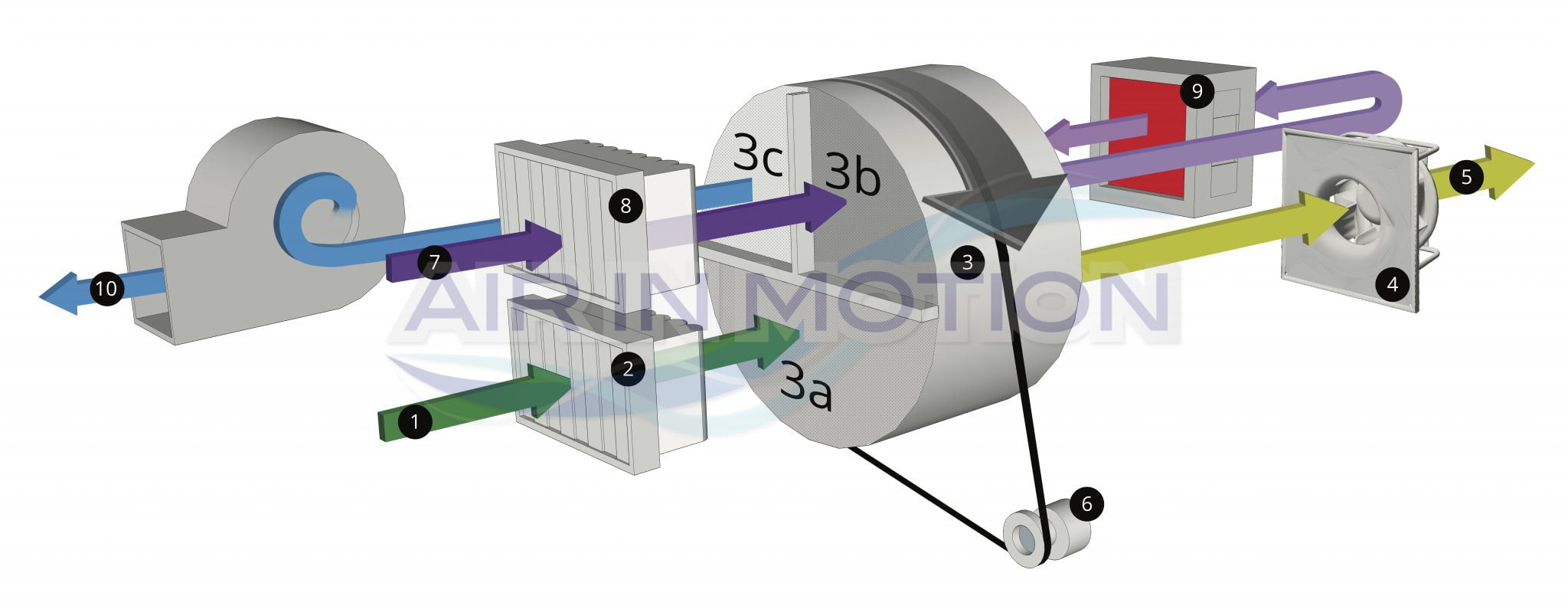

The process-air (1) is being sucked into the dehumidifier and blown through industrial bag filters (2). To guarantee a stable and continuous operation, these filters have a minimum overcapacity of 30%. After the process-air has been filtered, it continues through the process section of the rotor (3a). The surface of this rotor (3) is covered with small air channels that flow all the way through. These small channels contain a high amount of silica gel (>82% of the total surface). Because of the rotors unique composition, the moisture in the processed air is being adsorbed by the silica gel. When the process-air leaves the rotor, it’s completely dry. The process-air is pushed through the rotor due to negative pressure. This negative pressure is created by an industrial and energy efficient EC-fan (4). The dry air (5) is then expelled from the dehumidifier and ready for use. The rotor is continuously spun around slowly by the rotor motor (6). This way the rotor is always ready to pick up moisture.

The advantages of an industrial desiccant dehumidifier include that the drying process is continuous. The process is never interrupted by, for example: defrosting/de-icing. Furthermore, extreme low moisture levels can be reached with an industrial dehumidifier.

The regeneration-air (7) is being sucked into the dehumidifier and blown through industrial bag filters (8). To guarantee a stable and continuous operation, these filters have a minimum overcapacity of 30%. After the regeneration-air has been filtered, it continues through the heat recovery section of the rotor (3b). The heat recovery section recovers a minimum of 30% of the heat. That heat is being re-used for pre-heating the regeneration-air of the dehumidifier. After passing through the heat recovery section, the air is heated to over 100°C by the internal heater (9). The heated regeneration-air passes through the regeneration section of the rotor (3c). When the regeneration-air passes through the rotor, the air absorbs all the moisture contained by the rotor. The regeneration-air, also known as “wet air”, is then expelled out of the dehumidifier (10).